My master thesis- Development of 3D FDM Printer and implementation on the market

Finally, when I got to my final year in autumn 2015, I had to scale through some subjects, write my master thesis and got a degree.

For 5 years now, I had been passionate about 3D printing and also for 4 years I had been keenly interested in building my 3D printer. So the topic for my master thesis was a clear. Which was to build a 3D printer based on opensource RepRap and to also write a business plan how to sell my product. But it was very difficult to find a supervisor for that, because it encompass both business and engineering together. Finally I found Mr. Oskar Zemčik, who was a leader in RepRap at my University.

The easiest way on how to get to the topic was to find a community in the Czech Republic who were interested in 3D printing, one of them was a Makerslab in Prague, so I went there couple of times for workshops on how to work with a 3D printer. Next step was I have to meet with companies, one of which will be3D. I spoke more about business plan with the CEO and I also met with Mr. Prusa (the biggest producer of 3D printers in the world) and spoke more on working for them than a 3D printers. But It was impressive to see 45 RepRap 3D printers printing at the same time.

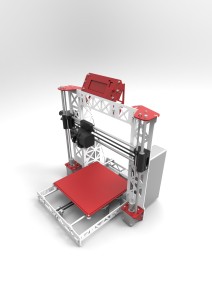

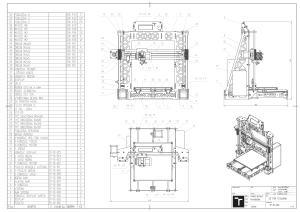

I bought my 3D printer Prusa i3 and it was a huge inspiration for my master thesis project. Then I tried to explore some of the weaknesses of the device which I can handle to improve upon. By virtue of my mechanical engineering skills I made a different frame (cheaper and more stable) and used open source operation system.

Business plan was part of my master thesis as well. I run cost analysis on all the parts for 3D printer of a type RepRap which cost about 200 EUR (depending on the componets where they were made from. Although those from China seems cheaper). Selling price in the market was almost double, but some of them cost almost 1000 EUR but they had a great customer service and brand.)

As I designed the 3D printer and also write a business plan, I had to carry out my final master thesis presentation, but the night before the presentation my display got broken, and it was very stresfull. Fortunutely for me, my flatmate recomended that i should change the LCD from older 3D printer which i did. The next morning I had a great presentation with amazing feedback from professors.

To write a master thesis was a challenging task, it took me about 300 hours, but I made it and now I can focus on other projects.

You can read my master thesis at https://www.vutbr.cz/

Thank you to my family, my friends and colleagues who help me to finish my studies.